Mould maker Kavia Tooling has developed its own machining strategies to run multiple CNC programs at once by merging several of them into a single file; many containing around 1.5-million lines of code.

Working out of 9000 sq ft premises in Burnley, with 15 employees, the company produces around 80 mould tools a year for plastic injection moulders, ranging in size from small tools of 156 x 156 mm, anywhere up to 2 tonnes. Key to the company’s throughput, Kavia has invested heavily in customising a range of software and equipment, including CAM solutions from Edgecam, and a Pioneer co-ordinate measuring machine (CMM) from Hexagon.

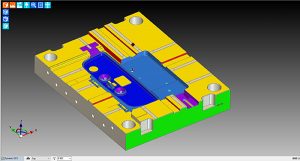

Edgecam drives seven high-speed CNC mills with spindle speeds varying from 12,000 to 30,000 rpm, and Sodick EDM machines, but production director Mark Cole says it’s no ordinary machining process: “Edgecam has customised the software to create a system for us which we call Merge. It means we can put several components on the machines at once, and the Edgecam CNC code for them is all merged into one large program, along with the datums to set the parts on.”

He cites a recent example when the company was working on two cavity plates on one side of the machine, and four inserts on the other. “We put the individual Edgecam CNC programs for each component together into one file, and it all went to the machine as one large program.”

The Merge strategy also helps to keep cutting tools to a minimum, by looking at information such as duplication, length and tool quality in all the programs. “For example, if there were two repeating cuttings tools in the individually merged programs, it selects the best one for the manufacturing process,” says Cole. “It goes through every single NC program and rearranges all the tools accordingly.

“If we have 10 components that can all fit on the machine, Merge puts the tool information for all 10 programs together: the datum setting information, part setting information, the pre-setter, everything,” he adds. “So as far as the machining is concerned, it’s just one big product.”

Cole says the benefits are “unbelievable”, creating a completely standardised system: “The customised software works for us exactly how we want it to, and everyone from the CAM programmer to an apprentice setting the tools, works in the same way. It demystifies shop floor activities and eliminates error.”

Kavia Tooling’s most recent investment in customisation is the unusual way of using a Hexagon Pioneer CMM. Rather than checking finished dimensions and ensuring a part is manufactured within tolerance at the end of the manufacturing process, Hexagon wrote a piece of customised software to enable Kavia to find offsets at the beginning of the operation.

Known as ‘Zero Transfer Fixture Plates’, this particular customisation means that instead of having to put each part on the machine and set it, the component is set on the CMM, which gives Kavia the X, Y, Z and U orientation. This can be done with any number of components, and the information is transferred to the machine through the Edgecam Merge software. Merge uses the data to add a programmed work offset and co-ordinate rotation into the appropriate merged programs.

“We only have to put the Zero Transfer Plate, which is micron-accurate, into position on the machine, and it knows exactly where the part is, so we don’t have to set it,” explains Cole.

The end result is a CNC program which can produce several parts at a time, without the need to use the machine as a set-up station as all preparatory operations are now carried out offline.

“Without the CMM, if we were setting up a component square on the CNC machine for example, we’d have to ensure it was perfectly in line with the machine’s axis,” says Cole. “If we were doing that for 10 components, the process would be prone to error, especially where there are overhangs. But setting them on the CMM means everything is done automatically, because it tells the machine the angle of the part.

“To set up six fairly difficult components directly on the machine might take one day, during which it’s not running,” he adds. “On the CMM it’ll be one hour, and you can be totally confident they’ll be absolutely accurate.”

Edgecam engineers also worked with Kavia Tooling on customising the software further, to set tooling data for the CNC programs offline by utilising data from the company’s Zoller tool pre-setter system. Previously, the operator had to manually set all the tools for each job run, with the same costs and risks associated with datum setting.

“Now, Zoller captures the required tool information for all the programs, and Edgecam merges it into the final CNC file,” says Cole. “It used to be a skilled job, but today a first-year apprentice does it.”

With some of the merged programs coming out at around 36 MB and containing up to 1.5-million lines of NC code generated by Edgecam, they can take four days to run.

“Our machine tools are generally operating 24/7, as they’re expensive and need to be running as long as possible,” states Cole. “A lot of our investment in bespoke software and automation was to create an environment where the machines are running while we’re doing as much preparatory work as we can offline.”

Kavia Tooling’s general philosophy is to run smaller programs during the day, and longer ones unsupervised overnight.

“We’ve also created a lot of systems through Edgecam where we combine a number of smaller runs that would each take half an hour, into a 12-hour night run,” he says.

“Edgecam is absolutely integral to our entire manufacturing process. It’s at the heart of everything, and is vital in terms of what it does through customisation, standardisation and the removal of errors.”

For further information www.edgecam.com