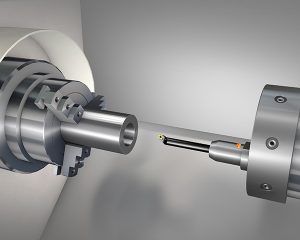

Sandvik Coromant has released the CoroChuck 935 high-precision hydraulic chuck for turning operations that is said to offer the market’s best pull-out security.

With CoroChuck 935, Sandvik Coromant says that machine shops can confidently perform demanding turning operations, including those with long overhangs. In fact, CoroChuck 935 ensures that a clamping length of four times the bar diameter can be achieved. Developed for use on lathes, turning centres and multi-task turn-mill machines, the chuck covers most common machine interfaces.

The design principle behind the high level of security offered by CoroChuck 935 is based upon fulcrum technology. A thin, brazed membrane offers an optimised clamping function whereby expansion creates two distinct clamping points on each side (fulcrums). The concept is said to ensure that the clamping force repeats for every use.

Additional benefits of the new chuck include the use of EasyFix sleeves to provide the correct centre height and help reduce set-up time. EasyFix sleeves are a solution for cylindrical boring bars that sees a spring plunger (mounted in the sleeve) click into a groove on the bar to guarantee the correct centre height. In addition, the metallic sealing offers good performance in applications that require high-pressure coolant.

CoroChuck 935 is available in 20 and 25 mm bore sizes to suit Coromant Capto, HSK-A/C/T, cylindrical shank and VDI machine interfaces.

For further information www.sandvik.coromant.com