A cutting-tool distributor has reduced a customer’s machining cycle on a complex aerospace component from 4 hours 20 minutes to just 93 minutes, by programming it with Edgecam.

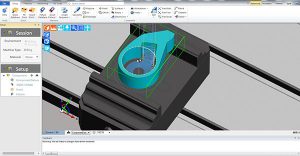

It was part of the technical solutions programme from Advanced Cutting Tools (ACT), where the company optimises customer machining strategies. The technical solutions programme is a partnership with Vero Software’s CAM package, Edgecam.

ACT owner and managing director Michael Richardson says the company now provides its customers with machining strategies and Edgecam CAM programming for specific parts. “Our philosophy is that the cutting tool you buy from us isn’t important, but what you do with it, is. So we look at the components our customers want to produce with the cutting tools, and what they’re looking to achieve with them. That may include increased productivity, greater efficiency or faster machining cycles. In many cases we’ll suggest changes to the strategies and give them an Edgecam program for optimum machining of the part.”

To ensure that the cutting tools are always implemented with the correct CAM strategies, two ACT employees have recently undertaken a four-day Edgecam training course, one of whom is Mark Ranft. “We introduce Edgecam to our customers whenever we believe that there’s an opportunity to improve their manufacturing process,” he says. “It gives our technical department considerably more depth and means we can offer an important added-value service, giving us a serious competitive edge.”

Ranft programs parts on Edgecam at customer premises, and says they can instantly see the benefits. “We’ve recently carried out a job where Edgecam reduced a cycle time by more than half, from 25 minutes to 12 minutes.”

For further information www.edgecam.com