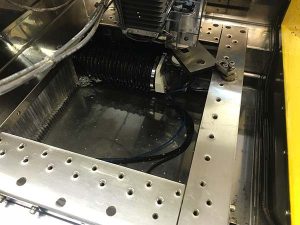

Redditch-based Vulco Spring & Presswork, which manufactures electrical installations, brackets, clips, clamps, flanges and wire-formed parts, has invested in a Fanuc Robocut C400iB EDM machine to help produce press tooling for its multi-forming machines and 20-70 tonne power presses “We have older EDM machines on-site but we’ve been struggling to locate the spare parts for these machines,” says production engineer Joseph Draper.

“Reviewing the market for a new EDM, the high-speed automatic wire feed on the Fanuc Robocut C400iB was one of the main reasons we bought the machine. This system will automatically feed the wire through a start hole and then the CNC program will begin to cut the job. Afterwards, this automatic feature will cut the wire, move to the next datum point and then process the next feature or hole. The machine will automatically continue to

process hole after hole, or

shape after shape.

“Previously, we had to manually feed the wire at the start point, start the machine and upon completion we’d cut the wire and move the workpiece or wire to the next point,” he adds. “What this gives us is the ability to leave the EDM work for significantly longer periods without intervention. Furthermore, we can leave the machine to run through the night unmanned and arrive in the morning to finished parts.”

For a manufacturer less familiar with the opportunity for unmanned operation or lights-out production, the Fanuc Robocut C400iB assures the end user with its automatic repair system, which will automatically repair the wire and continue production

For further information www.fanuc.eu