Kennametal says that customers have been asking for a new carbide grade to machine titanium 6Al4V at higher cutting speeds instead of having to increase feed rates or depth of cuts, which can result in greater cutting forces on the workpiece, fixture and spindle. With this in mind, the company’s latest KCSM40 grade has a cobalt binder that provides thermal fatigue resistance without sacrificing toughness. In addition to the new material substrate, Kennametal´s proprietary AlTiN/TiN coating is said to enhance wear resistance at the cutting edge.

The target cutting speed for KCSM40 in Ti6Al4V was 53 m/min, while hitting in excess of 327 cu cm/min metal removal rate for 60 minutes. According to Kennametal, not only did KCSM40 achieve this but showed the capability to mill titanium at speeds up to 85 m/ min at a lower radial depth of cut.

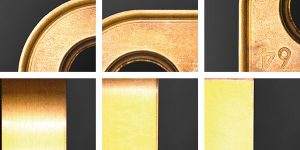

Recent internal testing with the new Harvi Ultra helical milling platform achieved over 100 minutes of tool life running at 47 m/min with a 0.12 mm/t chip load. Radial depth of cut was 25 mm and axial depth of cut was 76 mm. Kennametal says that the edge condition on the KCSM40 grade still looked great.

The company is also witnessing many other good results. For instance, in one face-milling operation on a hardened steel wear plate, the number of passes was reduced from 234 to just 22.

For further information www.kennametal.com