After seeing a decline in the precision grinding market in recent years, Nadjar company director Renaud Nadjar has expanded his Villeurbanne, France-based shop to take on a variety of other machining processes.

Nadjar’s first investment was in milling. Unimpressed by the programming software embedded in numeric control systems, Renaud Nadjar decided to equip the company with standalone programming software. He wanted to program more complex parts and undertake programming in the background while the machine was operating. He knew by talking to other subcontractors that there were problems with some of the solutions available on the market. Wanting to avoid those pitfalls, Nadjar decided to meet with several CAM software developers to help him make the right decision.

Nadjar discovered that the partnership between machine manufacturer Haas and Esprit CAM software made it possible to purchase both in a package deal. “Thanks to this partnership, we were able to start with certified post processors and error-free CAM,” he explains. Nadjar subsequently made an initial investment in three Haas machines with corresponding Esprit licences.

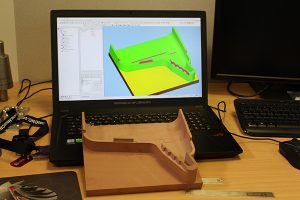

This successful initial experience led Nadjar to quickly buy an NC lathe with another Esprit licence and then another milling machine. However, the demand for 3D machining prompted the company to purchase the Esprit 3D milling module. It was a new challenge, but several months on, Nadjar is delighted with the investment: “As the software calculates everything, it prompts with coherent values, and we save an incredible amount of time. And of course, the results obtained are outstanding.”

The company has already exceeded its revenue forecast and plans to invest in five-axis milling and three- and five-axis turning next. “We are limited by our machines, but there’s no limit with Esprit CAM,” concludes Nadjar.

For further information www.espritcam.eu