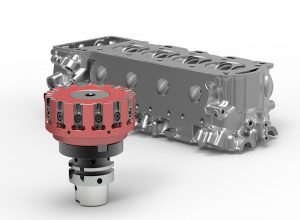

At the recent EMO exhibition in Hanover, Hainbuch introduced its latest mandrel system, the Maxxos T211. The segmented clamping bushing of the Maxxos T211 has an internal hexagon shape that fits on to the clamping pyramid to help maximise cutting performance.

Thanks to the hexagonal pyramid clamp, maximum torque transmission can be achieved. In comparison with the classic Mando T211 mandrel, the new addition to the Hainbuch line-up generates up to 155% more transmissible torque and up to 57% higher stiffness. This makes it possible to achieve higher machining parameters and consequently improve the yield of finished parts. Greater process reliability is facilitated by the spacious layout between the clamping bush and clamping pyramid. Even during the clamping process, this design prevents virtually any dirt or contaminants from getting on to the surfaces.

Overall, the Maxxos T211 mandrel has a clamping diameter range of 18 to 100 mm, while the clamping areas of each size are designed to overlap. The advantage of this configuration gives users the ability to choose from up to three mandrel sizes depending on the clamping diameter. With the Maxxos, the larger the mandrel, the greater its stability and rigidity. The aligned, segmented clamping bushings have a minimum concentricity of 0.01 mm and can even be supplied in a high-precision version.

For further information www.hainbuch.com