An injection mould manufacturer has seen a recent resurgence of tool making in its native Irish Republic, and says CAM software helped it through the recession by giving the company a competitive edge to work in high-end markets.

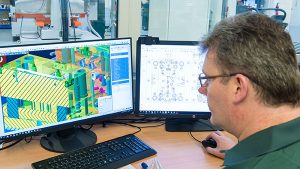

Alpha Precision, based in Tubbercurry, County Sligo, operates an almost full suite of VISI modules, which director Brendan Feely describes as a seamless communication tool.

“Several years ago Ireland experienced an exodus of tool-making contracts as work went overseas, particularly to China. At the same time, VISI CADCAM software for the mould and die industry was rapidly developing and adding new features. Even companies which weren’t computer literate were investing in the technology to survive. The software had a huge effect on the tool-making industry, giving us a competitive advantage to weather the storm.”

He says it’s now “high end all the way” for Alpha Precision – high-end staff building high-end mould tools with high-end software. “The technology promotes a more automated process, and means our staff need a different skillset nowadays, to use VISI to its full potential.”

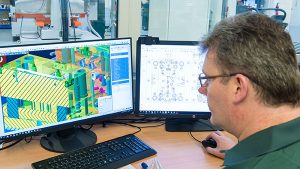

To explain fully how he feels VISI is the seamless communication tool that acts as the glue in the complete tool-making environment, he likens his tool room to a football team. “We need our goalkeeper, defenders, midfielders and strikers. We have a variety of different machines doing different jobs, so our operators have different skills. The software is applied on the back of the machining, and because there are several disciplines, such as design, milling, wire and spark eroding, the software fits naturally into its given area. The operator in that area is just trained on the one particular VISI module.”

Continuing the “team” analogy, Feely says the tool room is like a group of people from different countries with none of them speaking a language other than their own. “One language is design, with others including flow analysis, milling, wire EDM and spark erosion. VISI is the common language that unites all processes, ensuring everything moves fluently through the tool room from one discipline to another.”

Operating with 12 employees, the company produces an average of around 40 tools a year, ranging in size from 100 x 100 mm, up to 600 x 1000 mm, mainly for the automotive, medical, packaging and electronics sectors.

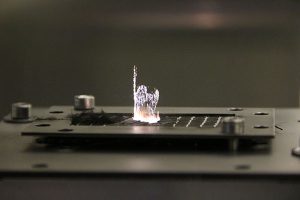

Two of the company’s current projects are: producing a number of high cavitation tools for one of its many medical customers; and a contract for two-shot plastic injection tools, which involves an over mould. “Although two-shot production adds another element by involving a second material and process, VISI keeps it simple and efficient.”

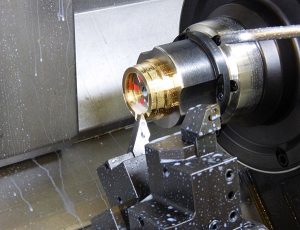

With VISI programs running the company’s high-speed milling on Röder and Makino machining centres, the challenges posed by the medical industry’s requirement for very fine micro levels, are readily overcome. “We use a 42,000 rpm spindle speed for very small detail finishing, and cut our electrodes on a Makino F3, with high definition being done on an F5. And we can also machine a cavity in just one night, which would otherwise take a week. Using VISI Machining we can quickly produce a highly polished medical part with fine detail, a milled finish and a split line, within micron accuracy.”

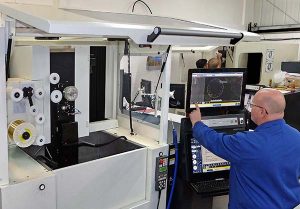

VISI also powers Alpha Precision’s Charmilles EDM machines for spark eroding and Mitsubishi wire eroders. He says parts of the tool will have been cut on each of the machines, and when it’s ready for shipping it is a very fine micron, accurately finished tool for, typically, the medical or automotive industry.

Having invested in many VISI modules including Modelling, Analysis, Flow, Mould and Progress, wire cutting and electrode systems, along with 2D Milling, 3D Milling and High Speed Milling, the software is used at every stage of the company’s process, beginning with providing an accurate quotation for the customer. “We use VISI’s analytical tools to check the drafts and all the different features we’ll need to build into the mould, such as the core and side pieces.

“When the order’s been placed, we work closely with our customers’ moulders on the design concept, including flow analysis and tool layout. Once the 2D design is broken down and we have the tooling in full 3D, we really begin to see the huge power of VISI, which controls everything from design, through milling to wiring in one environment. As we’re not going across translators there’s a perfect understanding within the technology, taking it right through every stage.”

Combining VISI’s Compass technology with its 2D and 3D milling capability, all milling for hard prepping and high-speed finishing is handled quickly and accurately, which Feely says is vital to the company’s operation. “We make a lot of one-off components for each mould, meaning we only run a program once. As pattern cutters we need to be very good at generating CNC code time after time, and VISI is exceptional at doing that job for us.”

Although injection mould tools form Alpha Precision’s core business, the company also provides a blow-moulding and forming-tool service, and has experience in specialised press tooling. However, Feely concludes by saying that the business is currently embarking on an exciting new journey, working closely with a major customer on injection rubber.

For further information www.visicadcam.com