Kennametal says it has solved the age-old problem of tool stability when drilling in deep cavities past tall shoulders or bulky fixtures. The company has developed a hydraulic chuck extension that meets these challenges, while increasing flexibility and reducing costs.

“We asked our customers how they drill holes in deep cavities and complex pockets,” explains Michael Schuffenhauer, senior global product manager tooling systems at Kennametal. “We wanted to know if they had problems with reaching past clamps and fixtures, how they were dealing with these issues, and the effectiveness of their existing solutions. Then we set out to develop a better one.”

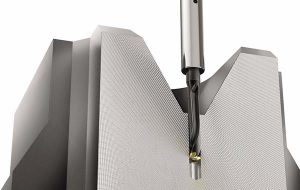

Kennametal’s line of hydraulic chuck (HC) extensions offers a number of key features that include: runout to within 3 µm at 2.5xD; balanced to G2.5 at 25,000 rpm; and a slim design that allows, for example, a 12 mm drill to be clamped in a 20 mm chuck body. Furthermore, various reducer sleeves are available for both metric and imperial sizes, helping to maximise flexibility.

The design, in fact, is simple: just set any h6 tool shank inside the HC extension and turn the clamping screw on the end of the unit until seated. This causes a hydraulic piston within the unit to move forward, compressing the locating sleeve, and gripping the tool.

“Our HC Extensions are for customers that need the flexibility of a modular system but want to avoid the expense and limitations of a custom solution, as well as the constraints that come with traditional tool holders,” says Schuffenhauer.

For further information www.kennametal.com